There are several ways to heat, cool and ventilate a home but probably the most popular method in North America is forced air. A central furnace, air-conditioning unit or heat pump is connected to the rest of the building with a network of venting.

There are several ways to heat, cool and ventilate a home but probably the most popular method in North America is forced air. A central furnace, air-conditioning unit or heat pump is connected to the rest of the building with a network of venting.

Vents can be used for three main purposes, to supply conditioned air, to return air back to the HVAC units, and to exhaust air that needs to be expelled from the home because it contains fumes, smoke or moisture.

The heating/cooling venting system can consist of round, oval or rectangular ductwork, which usually branch off of large plenums that connect directly to the HVAC unit. These can be made from sheet metal or from covering the space between joists and studs.

A blower forces conditioned air from the HVAC system into the supply plenum, and return air is collected from return ducts into the return plenum and drawn back into the HVAC unit, usually through a filter.

Duct materials

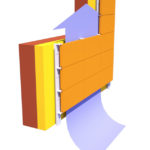

Ductwork can be made from various materials and can be flexible or rigid.

Flexible ducting (also called flex) is made from round, reinforced plastic tubing and is often covered with a layer of insulation and a protective coating. This is easy to install but not suitable for tight turns.

Metal ducting is usually galvanized to prevent rust and can be round or rectangular. It is strong and durable but easily cut and fabricated into tight bends.

Ductboard is a system that uses fiberglass panels that are easily cut. They are more energy efficient than other types of ductwork and also transmit less noise.

Often, a combination of flexible and rigid ductwork is used with metal for the main large ducts and flex running to the individual outlets.

Existing metal ductwork can be insulated to increase energy efficiency. This can also reduce condensation that could result in mold and mildew that, once blown around the house, can cause health problems. The most common method is to wrap fiberglass around the ductwork but spray foam can also be used.

Configuring a ductwork system

The size of ductwork affects the amount of airflow and its velocity and is very important in how well the HVAC system operates. Rectangular ducting can come in various sizes from 3” x 7” up to 35” x 40”; and round ducting can be anywhere from 4” to 41” in diameter. The heat registers and return grilles are also available in different sizes depending on the opening and can be made of metal, wood or plastic.

The calculations needed to determine the optimal size of ducting are complicated and there are several online calculators and tables available to do this.

Here’s what you need to think about when it comes to sizing ducts. Basically, the size of the ducts depends on the distance the outlet is from the HVAC unit, the output of the HVAC unit and the amount of area needing to be conditioned.

In the case of exhaust air, ducts are normally round and the optimal diameter is based on the airflow of the fan they are attached to. With range hoods, a minimum diameter of 4” works for fans with a CFM (cubic feet per minute) rating of less than 400. For higher ratings, sizes can go all the way up to 12” in diameter. In the case of clothes dryers, specialized, flexible metal ducting must be used to prevent the possibility of fires caused by the buildup of lint.