Extendable, flexible and comfortable. Those are just a few benefits of hydronic heating systems. For about a decade, geothermal or geo-exchange/ground source and water source hydronic systems have been a growing niche market when it comes to home central heating. But the high cost of installation and the difficulty fitting them into many buildings has limited their proliferation.

Extendable, flexible and comfortable. Those are just a few benefits of hydronic heating systems. For about a decade, geothermal or geo-exchange/ground source and water source hydronic systems have been a growing niche market when it comes to home central heating. But the high cost of installation and the difficulty fitting them into many buildings has limited their proliferation.

But, as governments implement more carbon reduction programs, adoption of hydronic systems is only going to grow, and, in particular, we are seeing an increase of air-source to water heat pumps (ASHP). This technology has evolved rapidly in the last ten years and is creating opportunity for HVAC professionals, equipment manufacturers and consumers. In a 2018 survey of Plumbing & HVAC readers, hydronic systems came in only second to tankless water heaters in growing trends in the industry.

Why ASHP?

ASHP is the right heating system at the right time.

It’s relatively easy to add extra piping for your auxiliary needs (e.g. swimming pool, spa), it can provide both space and zone heating using a variety of methods, and through radiant heat can provide the ultimate in-home comfort. There’s also virtually no heat loss as hydronic systems are well insulated, making them more energy efficient—a definite consideration when it comes to your HVAC planning. (A hydronic system may lead to a lack of forced air ventilation, in which case installing a ceiling diffuser might be necessary.)

In an ASHP hydronic system, an air-source heat pump heats and cools using a refrigeration cycle. In cooling mode, it extracts heat from the home to the air outside. In heating mode, the pump pulls heat from outdoors so has better heating efficiency than a traditional furnace.

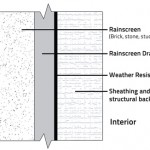

ASHP units require an outdoor evaporator coil (which becomes the condenser in cooling mode). The outdoor equipment needs to be placed within reasonable proximity to the indoor unit and interconnected with a refrigerant line set. The compressor is also usually located in the outdoor unit. Some have all of the equipment in the outdoor unit. Only the hydronic supply and water return lines penetrate the building envelope.

Although not as efficient—it requires more electrical power—ASHP is easier to install than geo thermal or geo exchange units and doesn’t have the cost of a ground-loop installation. ASHP units are also scalable. They are able to heat apartment-sized spaces as well as large commercial projects like schools and apartment buildings.

The current class of ASHP machines can directly substitute low-temperature hydronics and condensing boilers. Widespread adoption of gas condensing boilers over the last two decades means that ASHP integration can be seamless. Unlike condensing boilers, the refrigeration cycle can be reversed in hot weather to provide chilled water, which can be used for cooling when combined with the right equipment.

The future of hydronic systems

In the future, training in both hydronics and refrigeration/plumbing will be necessary.

Refrigeration engineers are able to grab heat from the ASHP machines for auxiliary loads, such as domestic hot water (DHW), pools and spa heating and even snow melting systems. They are also able to help the compressor work better at colder outdoor temperatures through another bit of heat-swapping that uses secondary heat exchangers to re-inject vaporized refrigerant back into the compressor.

A hydronic system that uses a heat pump as a source of heated water requires expertise in both hydronics and refrigeration. Trained technicians with expertise in both will have the advantage as the industry moves towards adopting more ASHP systems.

The development and enhancement of ASHP for hydronic systems is just beginning, with more innovations on the way. Countries in Europe and Asia have been especially quick to adopt the new tech. As we move towards a more carbon-neutral power grid, we’ll likely see hydronic systems become as ubiquitous as the condensing boiler.