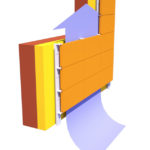

For many North American construction companies, rainscreens still represent a bit of a mystery. Finding experts in the field can be a challenge, but they do exist. In places like coastal Oregon and British Columbia, thousands of sealed building envelopes have been created with a breathable, capillary gap beneath the siding to allow water to drain or evaporate. That’s because their building codes require them. That makes them perfect areas to study what works and what doesn’t. If you’re looking for rainscreen experts, these are the places you will find them.

It’s also where you’ll find the headquarters for PrimexVents HVAC Venting Products. Langley, B.C. is at the heart of a region that learned the importance of dealing with water in walls the hard way. Rainscreens became mandatory in the late 1990s after thousands of condo owners were faced with devastating rot and mold issues.

The damage cost homeowners between $3 and $4-billion to repair. It happened in part because builders followed a code that allowed for the creation of walls that were susceptible to water penetration, while giving no opportunity for water to escape. Rainscreens were the solution.

Over the last fifteen years rainscreens have been standard procedure for British Columbia builders. The province has provided the ideal testing ground for associated rainscreen technologies. Early on, the construction industry learned the challenges of cutting holes through rainscreens. Every window, or hose bib, or vent created a new spot for moisture to potentially get behind a rainscreen’s inner membrane. That’s where PrimexVents stepped in with thoughtfully designed solutions to those venting worries.

Choosing materials to design vents

PrimexVents engineers carefully examined the vital elements required to vent a bathroom fan, dryer or range hood through a rainscreened wall. The first key was choosing the right material for the vents. Plastic resins proved ideal because of the ability to mold components in a single piece. That allowed PrimexVents to create a seamless base. No seams meant less potential for harmful leaks. Additionally, each wall cap was designed with an oversized flange. It made the application of the inner weather barrier over the vent easier, ensuring an effective seal.

PrimexVents also looked for innovations that would make maintenance of the ducting and rainscreen simple. A patented, removable hood was incorporated to allow access to the ductwork without breaking the building seal. This is particularly important for maintaining warranty protection. Through two decades of use alongside thousands of rainscreens, these technologies have proven their value.

Just like a chain, a weak link can spell disaster for a building envelope. That’s why choosing the right wall vents and other accessories that have been tested to help the envelope stay sealed is vital for modern builders who want to stand behind their work.